Custom CNC Machining

Our approach to CNC Machining is simple: Do the most cost effective solution to help the customer. We do detailed up-front DFM’s and have the latest software and equipment (including 3 axis, 4 axis and 5 axis).

The multi axis equipment allows us to minimize the number of sets ups and hence improve the precision, as well as keep the costs/prices economical. We are set up for PROTOTYPE as well as LOW, MEDIUM and HIGH Production CNC machined parts.

We can do CNC machining in the USA as well as in Asia.

Materials:

- Metals

- Alloy Steels – including Stainless Steel and Titanium

- Aluminums

- Copper/Copper Alloys and Plastics

- Plastics – POM, ABS, PC and More

EQUIPMENT – CNC MILLING up to 5 AXIS CNC Machining with LIVE PROBES.

Live Probes provide excellent feed back right at the machining area and allow us to hold tighter tolerances – often over larger distances and

HARD MILLING – Our high speed mills allow us to accurately machine hardened steels. It can save a lot of time and costs in making parts/tools

CNC TURNING – LATHES, SCREW MACHINES, THREADING,

BORING, GUN DRILLING. This equipment allows us to drill longer straight holes

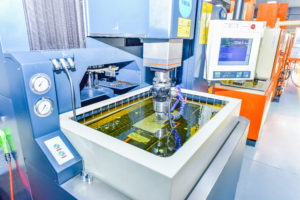

EDM – WIRE and SINKERS– Electronic Discharge Machining Erodes the metal with “sparks” ( AKA “burning”). With Wire EDM, we have a NC controlled wire that works like a super accurate “saw” and can move in curved paths.

With Sinker EDM, we create a shape and literally sink it into the metal – It allows us to do shapes that otherwise might have to be laminated in many pieces..

FORGING – WE can “press” (aka Forge or Stamp) a hardened tool into/onto a metal to force it to take a shape. Cold heading of bolts is a type of forging

LASER MACHINE/ENGRAVE. Just like milling, we can laser “etch” into metals. Usually used for smaller detailed metal removal instead of machining –

WELDING and BRAISING – Used to attach two parts (usually same metal), to make the completed part ( when needed – versus repair)

5 Axis CNC MACHINING is used to create complex parts using fewer setups and fewer fixtures. This also improves Accuracy and surface finish.

All finishes including platings, E-Coat, Wet Coat, Powder Coat, Chem Films, Andoize and PV Coating.

- Tolerances (including GD&T call outs) and functional Datums

- Surface finishes – up to Optical finishes